This chapter contains the following topics:

Introduction to Shop Order Materials

Delete All Requirements For A S.O.

This Inventory Management function is included on the Manufacturing Job Costing menu for convenient access.

Shop Order Material Requirements are the detail of a component item's total Quantity Allocated at a Warehouse. These "pegged" requirement records, identified to specific parent item Shop Orders, are also used to record actual issue quantity vs. required (planned usage) quantity for each controlled component.

If your bills of material are very simple, you may use this function to define component material requirements for each parent order added in the "Shop orders" function, instead of using the "Explode" shop orders program to create these records with a computer bill of material.

If you use the "Explode" shop orders program, you may wish to use this function to adjust exploded Shop Order Material Requirements for subsequent bill of material revisions or for minor component changes related to a specific Shop Order. If no material has been issued to an exploded Shop Order, you may also delete all related Material Requirements with a single transaction and then re-explode the order using an updated bill of material.

Maintaining Shop Order Material Requirements also updates other data as follows:

| • | Addition of a Material Requirement record increases Quantity Allocated in the component Item Master or Branch Warehouse Item record by the Component Quantity Required. Change of Component Quantity Required in a Material Requirement record adjusts item Quantity Allocated. Deletion of a Material Requirement record decreases item Quantity Allocated. |

| • | Addition of a Material Requirement record changes the Order Status code in the parent Shop Order record to E (Exploded), if Order Status was O (Open) before the Material Requirement was added. Deletion of all Material Requirement records for a Shop Order changes the Order Status code to O (Open) in the parent Shop Order record. |

The combination of Shop Order Number, Release Number, Parent Item Number on the order, and Component Item Number establishes a unique Shop Order Material Requirement record.

Select

Enter from the Shop order materials menu.

The following screen displays:

Enter the following fields:

1. Shop order #

Entry Format: Up to 6 alphanumeric characters.

Rls #

Entry Format: Up to 2 numeric digits, or default of space.

Validation: The combination of Shop Order Number and Release Number must match a Shop Order record.

2. Parent item #

Entry Format: Up to 15 alphanumeric characters, or

Press F1 to consecutively display Item Numbers with the Shop Order Number and Release Number you have entered, until you answer Y to "Right item # ?"

Validation: The combination of Shop Order Number, Release Number, and Parent Item Number must match a Shop Order record.

3. Warehouse

Entry Format: Up to 2 alphanumeric characters, or default.

Default: The Warehouse code in the first Shop Order record on file matching your Shop Order Number, Release Number, and Item Number entries is displayed as the default.

Validation: This entry together with Shop Order Number, Release Number, and Parent Item Number must match a Shop Order record.

At this point, the program will tell you if the parent Shop Order you have identified is closed, in which case you are returned to the Shop Order Number entry position. If the Shop Order is not closed the following data is displayed from the Parent Shop Order record:

Parent Qty Ordered

Order Due Date

Order Start Date

4. Component item #

Entry Format: Up to 15 alphanumeric characters.

Validation: Must match an Item Master.

When the combination of Shop Order Number, Release Number, Parent Item Number, and Component Item Number matches a record, then the remaining fields are displayed.

Comments: Enter spaces to select by description to search for an Item Number by entering any portion of the first 30 characters of its Description.

Press F1 to consecutively display Item Numbers with the Shop Order Number and Release Number you have entered, until you answer Y to the "Right item # ?" question.

5. Component qty per

Entry Format: Up to 3 numeric digits, plus 4 decimals.

Comments: If Product Definition & Costing is installed and the P/D Control Information entry is Y for "Use option to define product structure component qty per 1000 parent units ?", you are prompted to enter a parent quantity code (M for 1000 or space for 1 parent units) just before you enter the "Component quantity per" value.

Comments: The program will multiply this quantity by the Parent Order Quantity to calculate Component Quantity Required. If you entered a parent quantity code of "M", the Parent Order Quantity is divided by 1000 in this calculation.

6. Scrap allowance pct

Entry Format: Up to 3 numeric digits plus 1 decimal, or zero.

Comments: The calculated value of Component Quantity Required will be automatically inflated by this percentage.

7. Component due date

Entry Format: 6 numeric digits, in MMDDYY format, or default.

Default: Displayed default is Start Date of the parent Shop Order.

Validation: Must not match a date in Schedule Exception Dates.

After these entries the following additional data is automatically displayed from the Material Requirement record:

Component qty reqd Automatically calculated by the program as:

Parent Qty Ordered x Component Qty Per x (Scrap Allowance Pct / 100)

WIP qty scrapped

Set to zero when adding a record.

Qty issued

Set to zero when adding a record.

Issued date

Set to spaces when adding a record.

Returned date

Set to spaces when adding a record.

Pick list item ?

Set to Item Master value when adding a record.

Controlled item ?

Set to Item Master value when adding a record.

Except for indirect change to Component Qty Reqd by changing its calculation factors, you are not allowed to change the unnumbered fields which are updated by other Inventory Management programs.

You are not allowed to remove a Material Requirement record with a non-zero Qty Issued value. You must first return issued material to stock in Process Inventory Transactions before the delete is allowed in this application.

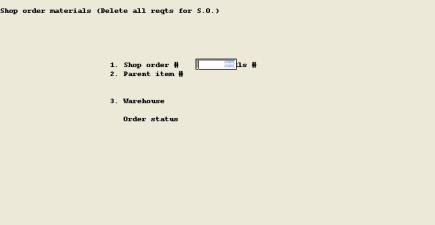

Use this application to remove all Material Requirements records for a parent Shop Order that has a current Order Status Code of E (Exploded).

Select

Delete all reqts for S.O. from the Shop order materials menu.

The following screen displays:

Enter the following fields:

1. Shop order # and Rls #

2. Parent item #

3. Warehouse

After entering the above fields, the Order Status displays.

If the Order Status is not E (Exploded), a message will inform you that "Delete not allowed for this order status". Otherwise, your are asked "Are you sure ?" Answer Y to delete all Material Requirements for the order.

You may also automatically delete Shop Order Material Requirements for orders with a status of E (Exploded) or I (Issued) by closing the parent Shop Order in Close Shop Orders.